Comparative Analysis of Steel Wire Armoured Cables and Aluminium Armoured Cables

In the realm of electrical installations, the choice of cable type is crucial for ensuring safety, efficiency, and durability. Among the various options available, steel wire armoured cables and aluminium armoured cables are two prominent choices. Both types serve critical functions in protecting electrical conductors, but they possess distinct characteristics that make them suitable for different applications.

Steel Wire Armoured Cable (SWAC) is renowned for its exceptional strength and durability. This type of cable is particularly suited for environments where mechanical protection is paramount, such as construction sites, industrial facilities, and outdoor applications. The steel wire armouring provides a robust shield against physical damage, ensuring that the cables can withstand impact and stress. Additionally, steel wire armoured cables are resistant to rodent attacks, making them ideal for installations in areas where such threats are prevalent.

On the other hand, aluminium armoured cables present a lighter alternative. While they may not match the strength of steel wire armoured cables, aluminium armoured cables are still highly effective in protecting the underlying conductors. Their lightweight nature makes them easier to handle and install, which can cause reduced labor costs and quicker project timelines. This makes aluminium armoured cables a popular choice for overhead lines and applications where weight is a significant consideration.

When comparing the thermal conductivity of both types, copper armoured cables often come into play as a third option. Although not the main focus of this analysis, copper armoured cables provide outstanding conductivity, which is a critical factor in many electrical installations. However, for the purposes of comparing steel and aluminium armoured cables, it is essential to note that copper cables are generally more expensive, which may limit their use in larger projects.

Cost Considerations

Cost is a significant factor when selecting between steel wire armoured and aluminium armoured cables. Steel wire armoured cables typically come with a higher price tag due to the cost of materials and the manufacturing processes involved. However, their durability and longevity often justify this initial investment. In contrast, aluminium armoured cables are generally more affordable, making them an attractive option for budget-conscious projects. The choice often boils down to whether upfront savings are more critical than long- durability and protection.

Corrosion Resistance

Another important aspect to consider is corrosion resistance. Steel wire armoured cables, while strong, can be susceptible to rusting if exposed to moisture without adequate protection. In environments where humidity or corrosive substances are prevalent, this can cause premature failure. To mitigate this risk, these cables often undergo additional treatments or coatings to enhance their corrosion resistance.

Aluminium armoured cables, on the other hand, have a natural advantage in s of corrosion resistance. Aluminium forms a protective oxide layer when exposed to air, which helps prevent further corrosion. This characteristic makes aluminium armoured cables particularly suitable for outdoor installations and marine environments where exposure to saltwater and other corrosive elements is common.

Electrical Performance

When it comes to electrical performance, both steel and aluminium armoured cables have their strengths. Steel wire armoured cables generally provide better mechanical protection but may have lower thermal conductivity compared to their aluminium counterparts. Aluminium armoured cables, while lightweight, offer good conductivity and are suitable for various applications.

The choice of cable often depends on the specific electrical requirements of the project. For instance, in high-current applications, the lower resistance of aluminium may prove advantageous, while in situations where mechanical stress is a concern, steel wire armoured cables may be preferred.

Installation and Maintenance

The ease of installation is another factor that can influence the choice between steel and aluminium armoured cables. The lightweight nature of aluminium armoured cables simplifies handling and installation, particularly in challenging environments. This can cause significant labor savings, especially in large projects requiring extensive cabling.

Maintenance is generally lower for both types, but the longevity of steel wire armoured cables may reduce the need for frequent replacements or repairs. However, if corrosion is a concern, maintenance strategies will need to be implemented to ensure the longevity of steel cables.

Both steel wire armoured cables and aluminium armoured cables offer unique advantages and drawbacks that cater to different needs in electrical installations.

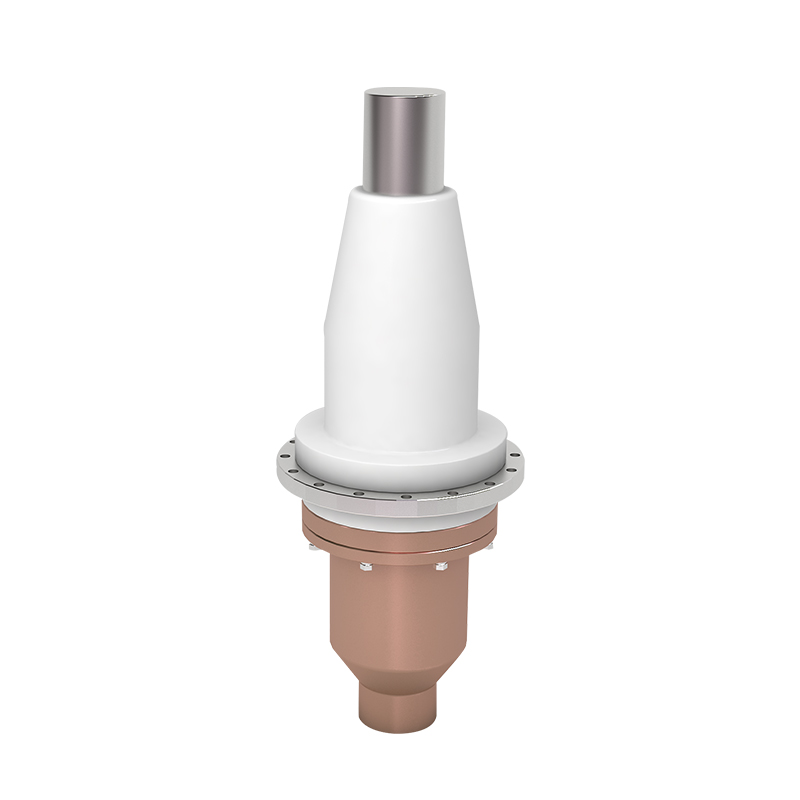

Recommended Products

The variety of models, to meet the development needs of various regions in the world.

-

Add: No. 508, Dongye Road, Dongjing Town, Songjiang District, Shanghai

-

Tel: +86-13757652508

-

E-mail: [email protected] [email protected]

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى