High Voltage Condenser: Navigating the Impact of Temperature, Humidity, and Pollution

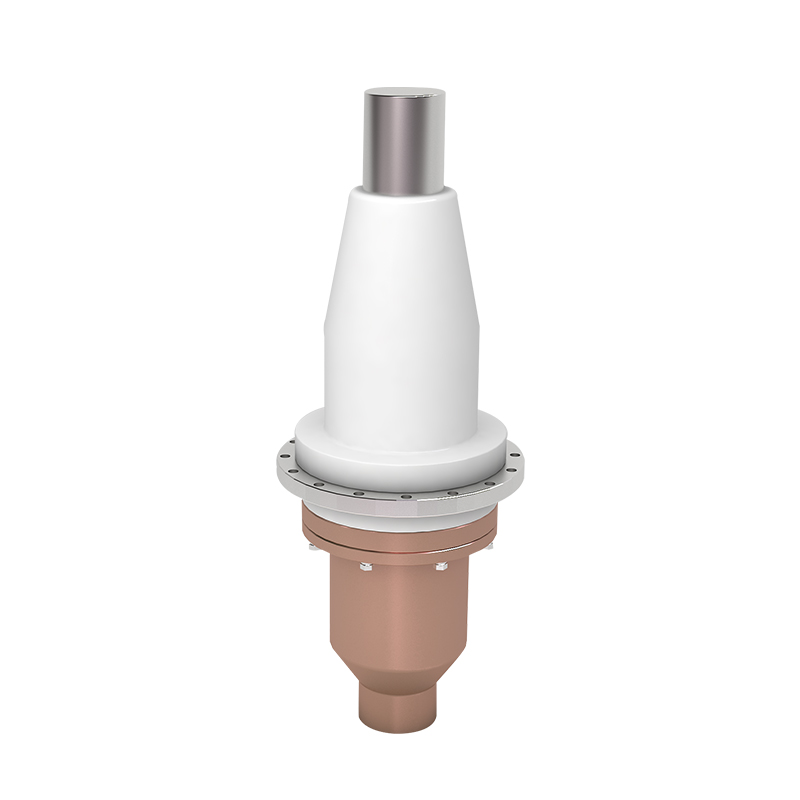

OEM high voltage condenser capacitor Manufacturer

The performance of a high voltage condenser is crucial in various applications, particularly in industries that deal with electrical energy storage and transmission. A high voltage condenser, commonly known as a capacitor, plays a significant role in electrical circuits, ensuring stable energy flow and serving functions such as filtering, energy storage, and voltage regulation. The behavior and efficiency of a high voltage condenser can be significantly influenced by various environmental conditions, including temperature, humidity, and pollution levels. Understanding how these factors affect the performance of a high voltage condenser is essential for optimizing its application and longevity.

Temperature is a critical factor affecting the operation of a high voltage condenser. Capacitors are temperature-sensitive components, and their capacitance values can change with fluctuations in ambient temperature. Generally, as temperature increases, dielectric materials used in capacitors may experience a reduction in their insulating properties, which can lead to a decrease in capacitance. This phenomenon is particularly evident in high voltage condensers made from organic dielectric materials. Elevated temperatures can also result in increased leakage current, which further diminishes efficiency and overall performance. On the other hand, extremely low temperatures can lead to brittleness in materials, potentially causing mechanical failure in the condenser. Therefore, a high voltage condenser must be chosen carefully based on its operating temperature range to ensure reliable performance in specific applications.

Humidity is another environmental condition that can influence the behavior of a high voltage condenser. High humidity levels can lead to increased moisture absorption in the dielectric materials of the capacitor. This moisture can significantly degrade the insulation properties, causing a decrease in the condenser's ability to store charge effectively. In applications where high voltage condensers are exposed to humid environments, such as outdoor power distribution systems, the risk of dielectric breakdown increases, potentially leading to catastrophic failures. To mitigate these risks, manufacturers often incorporate moisture-resistant materials and coatings in the design of high voltage condensers. Additionally, regular maintenance and inspection can be critical in environments with high humidity to ensure that the condenser remains operational and effective.

Pollution is another significant factor that can impact the performance of a high voltage condenser. In industrial and urban areas, airborne contaminants such as dust, dirt, and chemical residues can accumulate on the surface of capacitors, leading to insulation degradation. Pollutants can form conductive paths on the surface, increasing the likelihood of arcing and dielectric failure. In environments where high voltage condensers are exposed to significant pollution, specialized designs and coatings can be applied to enhance resistance to contaminants. For instance, hydrophobic coatings can repel water and pollutants, helping to maintain the performance integrity of the condenser. Regular cleaning and inspection in polluted environments are essential practices to prevent performance degradation and ensure longevity.

In addition to temperature, humidity, and pollution, other factors such as vibration, pressure, and mechanical stress can also affect the reliability of a high voltage condenser. Vibration is particularly detrimental in applications like wind turbines and substation equipment, where capacitors are subjected to continuous movement. Prolonged exposure to vibrations can cause internal mechanical failures within the condenser, leading to reduced efficacy or total failure. Manufacturers typically address this concern by designing high voltage condensers with robust internal structures that can withstand mechanical stress and vibrations.

Pressure changes, especially in applications at high altitudes or in pressurized environments, can also impact the performance of a high voltage condenser. The dielectric material used in the capacitor may behave differently under varying pressures, potentially affecting capacitance and insulation properties. High voltage condensers intended for use in such conditions must be designed to accommodate pressure variations to maintain reliable performance.

Furthermore, aging and wear can affect high voltage condensers over time. As capacitors accumulate service hours, their performance can degrade due to dielectric loss and other aging mechanisms. High voltage condensers typically have specified life expectancies, which are influenced by both their operating environment and the quality of the materials used in their construction. Conducting regular inspections and implementing preventive maintenance can help identify potential issues before they lead to failures, extending the life of high voltage condensers.

To summarize, the performance of a high voltage condenser is significantly influenced by environmental conditions such as temperature, humidity, and pollution. Each of these factors can lead to changes in capacitance, increased leakage currents, and overall degradation in the performance of the capacitor. For optimal performance, high voltage condensers must be selected and maintained based on the specific environmental conditions in which they operate. This includes choosing appropriate materials, implementing protective coatings, and conducting regular inspections to address potential issues proactively. Understanding the interactions between high voltage condensers and their environments is essential for ensuring safe, reliable, and efficient operation in various applications, from power generation to telecommunications. As industries continue to target higher efficiency and reliability in their electrical systems, a thorough comprehension of how environmental factors affect high voltage condensers will remain a focal point in engineering and design practices. By paying close attention to these influences, engineers can develop and utilize high voltage condensers that meet the demanding requirements of modern technologies.

Recommended Products

The variety of models, to meet the development needs of various regions in the world.

-

Add: No. 508, Dongye Road, Dongjing Town, Songjiang District, Shanghai

-

Tel: +86-13757652508

-

E-mail: [email protected] [email protected] [email protected]

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى