Safety Practices for Handling and Storing Microwave High Voltage Capacitors

As industries increasingly rely on high voltage technologies, the safe handling and storage of components like microwave high voltage capacitors have become paramount. These capacitors are critical in various applications, particularly in microwave and RF equipment. However, their high voltage characteristics necessitate rigorous safety practices to prevent accidents and ensure the safety of personnel.

Microwave high voltage capacitors are designed to operate at elevated voltage levels, often exceeding 1,000 volts. Due to their capacity to store significant electrical energy, mishandling can cause serious hazards, including electric shock or equipment failure. Therefore, understanding the proper procedures for handling and storing these components is essential.

One of steps in ensuring safety when working with microwave high voltage capacitors is to use appropriate personal protective equipment (PPE). Technicians should wear insulated gloves, safety goggles, and flame-resistant clothing. This protective gear is critical as it minimizes the risk of electrical shock and protects against potential thermal injuries should a capacitor fail during handling.

Before working with microwave high voltage capacitors, it's crucial to discharge them properly. Even when disconnected from power sources, these capacitors can retain high voltage for an extended period. Utilizing a resistor or a specialized discharge tool, technicians should carefully short the inals of the capacitor to safely release any stored energy. This practice is especially important for large high voltage capacitors, as the stored charge can be formidable and hazardous.

When storing microwave high voltage capacitors, it's essential to follow specific protocols to mitigate risks. First, capacitors should be stored in a controlled environment, ideally in a dry, cool place away from direct sunlight and moisture. High humidity can cause degradation of the capacitor's insulating materials, increasing the risk of failure when re-energized.

Organizing storage spaces for high voltage capacitor banks is another vital aspect of safety. Capacitors should be clearly labeled and stored in designated areas that prevent accidental contact. Using insulated racks or containers can help to minimize the risk of accidental discharges. Additionally, ensure that storage areas are accessible only to trained personnel to reduce the likelihood of unauthorized handling.

Regular inspections of microwave high voltage capacitors are also critical for maintaining safety. Before installation or after storage, technicians should check for any signs of physical damage, such as cracks or bulges in the casing. Capacitors showing signs of wear or damage should be tagged for repair or replacement immediately. This practice ensures that only reliable components are put into service, reducing the risk of failure during operation.

Education and training play a significant role in the safe handling of microwave high voltage capacitors. Companies should implement comprehensive training programs that cover the properties of high voltage capacitors, potential hazards, and safe handling techniques. Regular refresher courses can help keep employees informed about the latest safety protocols and technological advancements.

In addition to employee training, creating a culture of safety within the workplace is vital. Management should encourage open communication about safety concerns and ensure that proper reporting mechanisms are in place for incidents or near-misses. By fostering an environment where safety is prioritized, organizations can significantly reduce risks associated with handling and storing high voltage capacitors.

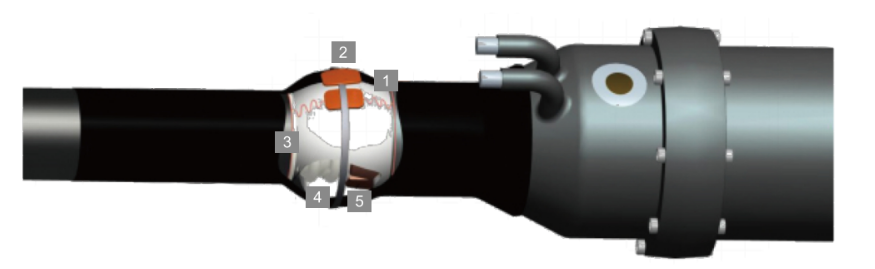

Technological advancements are also contributing to improved safety practices. Innovations in capacitor design, such as integrated safety features, can enhance reliability and reduce the risk of failure. Additionally, the use of smart monitoring systems for high voltage capacitor banks allows for real-time assessment of capacitor health. These systems can provide alerts regarding potential issues before they escalate, ensuring timely maintenance and reducing the risk of accidents.

Understanding the regulations and industry standards surrounding microwave high voltage capacitors is essential. Compliance with safety guidelines set forth by organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) can help organizations implement effective safety practices. Regular audits and assessments against these standards can further enhance workplace safety.

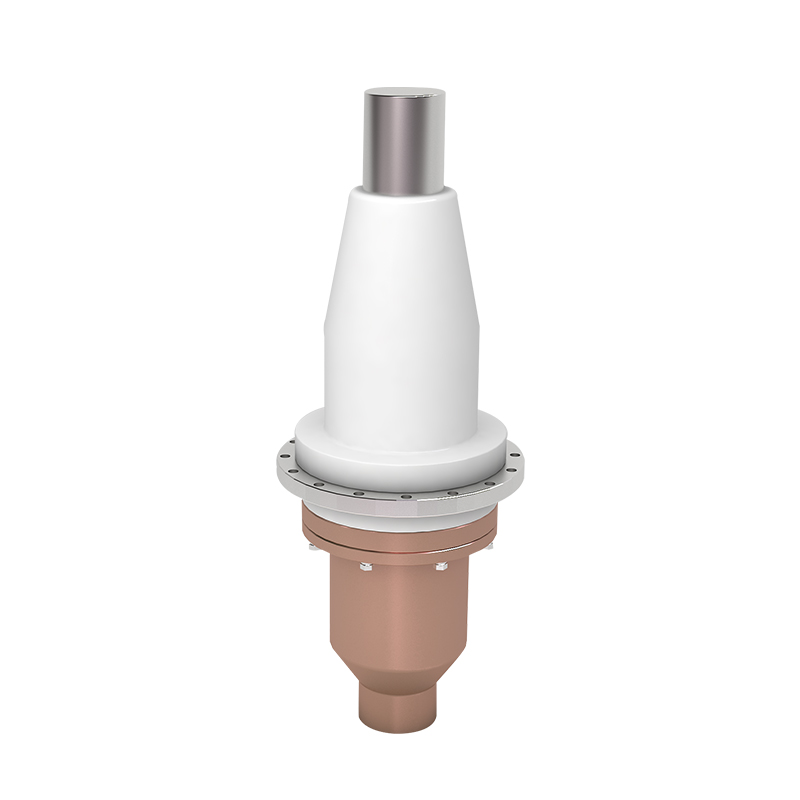

Recommended Products

The variety of models, to meet the development needs of various regions in the world.

-

Add: No. 508, Dongye Road, Dongjing Town, Songjiang District, Shanghai

-

Tel: +86-13757652508

-

E-mail: [email protected]

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى