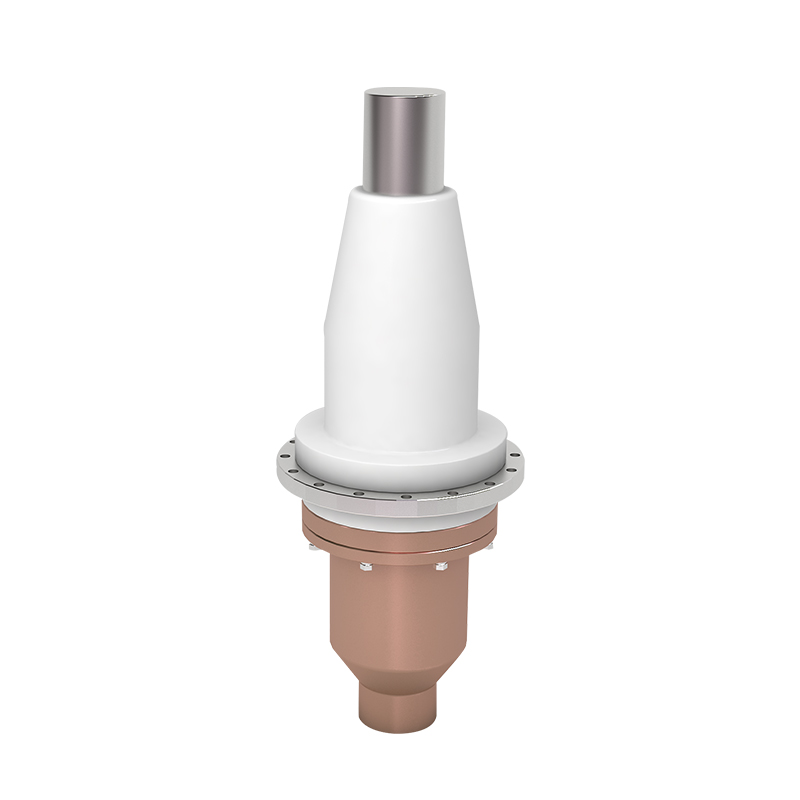

High Voltage Capacitors Equipment

Pole Mounted High Voltage Automatic Compensation

Application and Scope

The Pole Mounted High Voltage Automatic Compensation is suitable for 3kV and 10kV distribution lines. It is installed on overhead lines to improve power factor, reduce line losses, save energy, enhance voltage quality, and can also be installed indoors.

Structure and Working Principle

The device consists of or includes drop-out fuse, zinc oxide arrester, voltage transformer-type power supply transformer, capacitor switching special high-voltage vacuum contactor, current transformer, full-film high-voltage shunt capacitor, high-voltage capacitor automatic control device, and stainless steel enclosure.

Working Principle:

1. Closing the drop-out fuse connects the high-voltage power supply of the device. The secondary circuit connects to a 220V power supply, and the outdoor high-voltage capacitor automatic control device starts working. When the voltage, power factor, or operating time of the line is within the preset switching range, the controller activates the high-voltage contactor, which engages to connect the capacitor bank to the line. When the voltage, power factor, or operating time of the line is outside the switching range, the controller activates the intermediate relay of the trip circuit, causing the vacuum contactor to trip, and the capacitor bank is disconnected from the line. This achieves automatic switching of the capacitors, aiming to improve power factor, reduce losses, save energy, and enhance voltage quality.

2. When the line voltage exceeds the overvoltage protection setting (1.1-1.3Un), the controller delays 30 seconds before tripping the vacuum contactor and disconnecting the capacitors (the contactor doesn’t trip if the line voltage returns to normal within 30 seconds). After the contactor trips, when the line voltage returns to normal, the controller delays 10 minutes before closing the contactor and reconnecting the capacitors.

3. When the line voltage drops below 0.6Un, the contactor trips after a delay of 0.2-0.5 seconds. When the line voltage returns to normal, the controller delays 10 minutes before closing the contactor.

4. If the current of the capacitor bank exceeds the overcurrent protection setting (1.4-1.5In), the controller delays 5 seconds before tripping the contactor. If there is interphase breakdown of the capacitors, the contactor trips with a delay of 0.2-0.5 seconds, and the controller self-locks.

5. In case of interphase short circuit, the drop-out fuse quickly removes the faulty phase, and the contactor trips with a delay of 0.2-0.55 seconds and does not switch on again.

The device can be designed with adjustable capacity levels, up to three levels, and control modes including voltage, time, time and voltage, power factor, voltage and reactive power, according to actual requirements.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى